In the tangled field of cable maintenance where precision and longevity is paramount, the use of modern tools like wire rope lubricators as well as wire cleaners has become indispensable. These devices are innovative and have a crucial role to play in ensuring the smooth operation and prolonged lifespan of cables across various industries. This article discusses the importance of wire rope cleaners as well as lubricators for cable maintenance. We also examine their benefits and roles.

Understanding wire Rope Lubricators

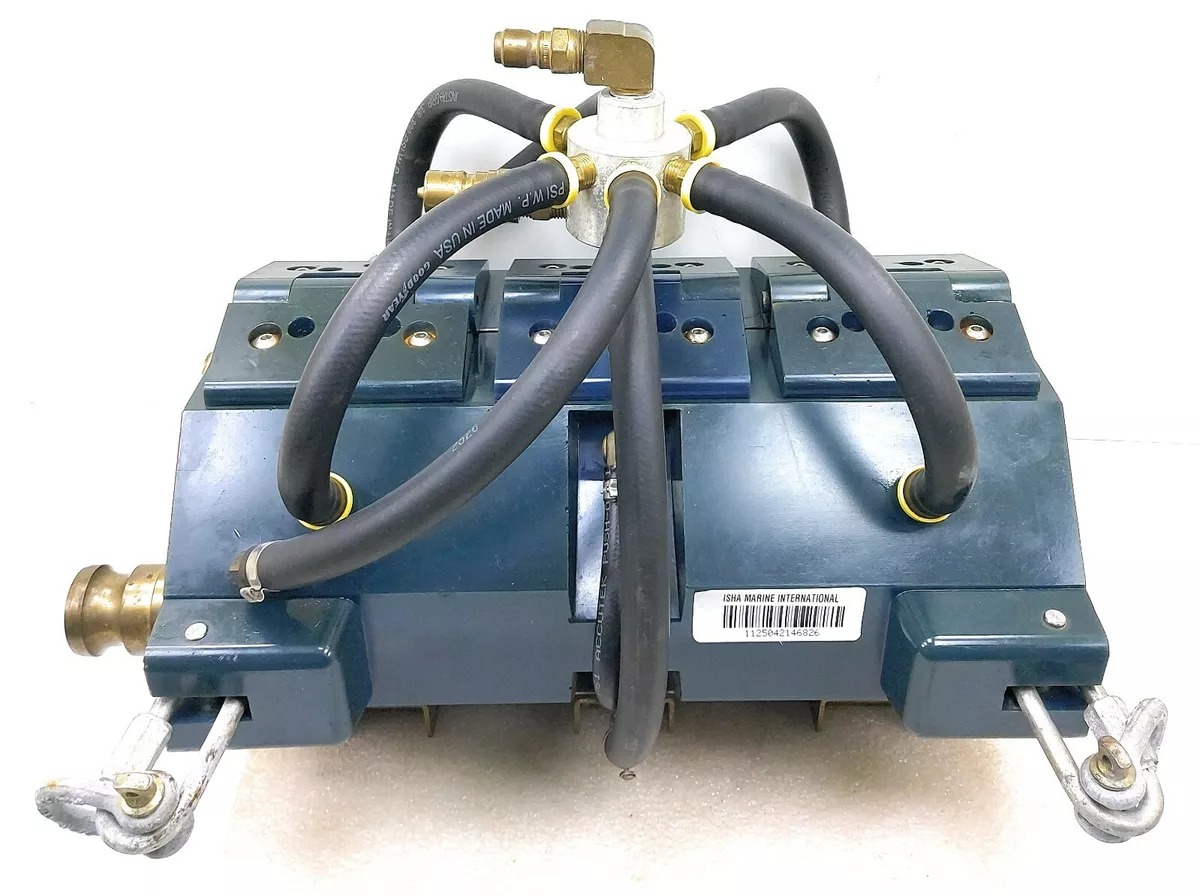

Wire Rope Lubricators are devices designed to help grease wire ropes in an orderly manner. This is necessary to prevent rust, while reducing friction, and enhancing overall durability. The lubricator distributes lubricant evenly across the length and widening of the wire rope in order to give complete protection against wear.

What’s the purpose of wire cleaners in the maintenance of cables?

Cleaners for wires (also called cable cleaners) are also essential to maintaining the hygiene and cleanliness of cables. They are specifically designed to eliminate contaminants, debris, and fluids that might build up over the cable during various activities. In environments with harsh conditions it is essential to use wire cleaning products is necessary to ensure the highest performance.

Optimizing Cable Lifespan:

Combining wire cleaning products with wire rope lubricators can extend the cable’s lifespan. Wire cleaners as well as wire rope lubricators work together to apply lubrication to the cables and remove the pollutants. This protects the cables from corrosion, friction and other external elements. This safeguarding of the cable’s integrity translates into prolonged operational efficiency and reduced maintenance costs in the long run.

Effectiveness when applied

Wire rope lubricators are made to make use of easy and effectiveness in their application. They are suitable for many different types and sizes wire ropes. They offer a variety of options in maintenance techniques for cables. The automated and systematic application of lubrication ensures consistency that eliminates the danger of uneven coverage that manual methods can cause.

Ability to adapt to challenging environments

The flexibility of wire rope cleaners and lubricators is essential in any industry that exposes cables to harsh environments. This includes drilling, construction, or maritime activities. These equipments are designed to endure harsh conditions and are reliable cable maintenance tools in a variety of situations.

Cost-Effective Maintenance Solutions for

Adopting a proactive method of cable maintenance through the use of lubricators for wire ropes and wire cleaners can be cost-effective in the long run. The upfront investment in these advanced tools pales in comparison to the costs associated with cable replacements along with downtime and costly repairs caused by ignoring good maintenance procedures. Know more at Wire Rope Lubricator

Conclusion:

Lubricators for wire ropes along with cleaners of wires, are the guardians of cable integrity. They assure accuracy, durability and maximum performance in all industries. Systematic lubrication of cables and elimination of dirt reduces maintenance costs and increases efficiency in operation. Cables are still utilized in critical industries, so adopting cable maintenance tools that will help maintain their reliability and performance is a must.